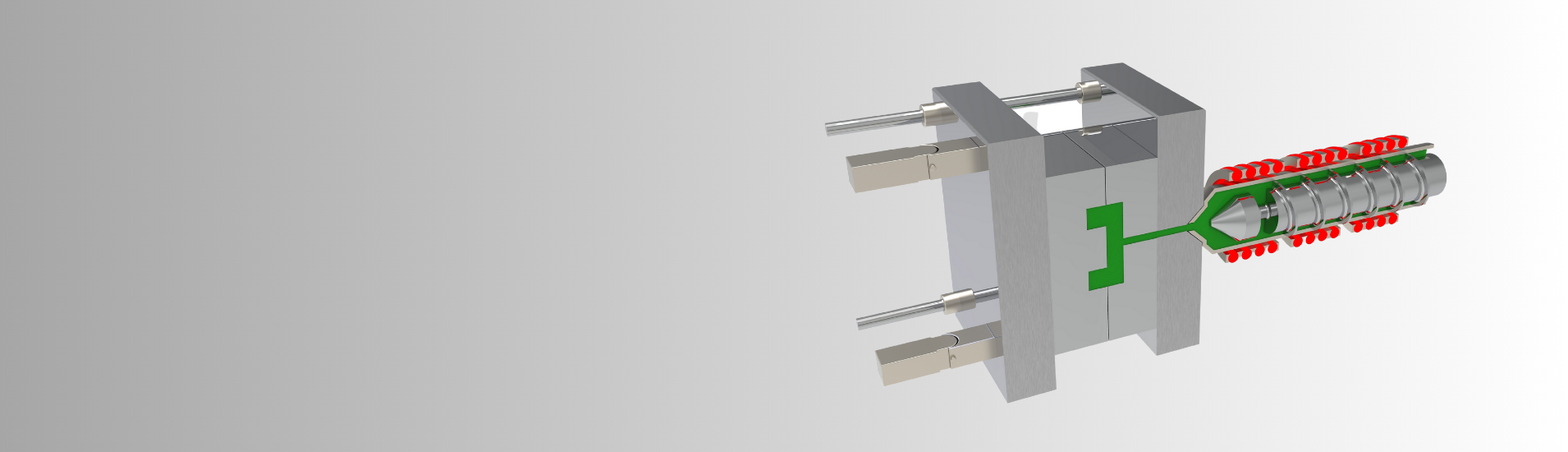

Injection Molding Processes

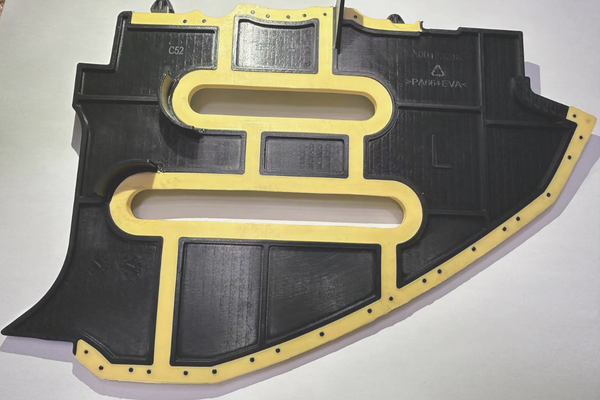

With cost-effective and high-quality to produce plastic parts, the process is a plastic or resin material heated to the melting point, then injected into the mold cavity and formed. Once it cools, the parts will be released from the mold. Repeat hundreds or more thousands of times, then you will obtain a large volume of injection molded parts.

The most cost-effective way to make a plastic part at scale and offers consistent quality for low-to-high volume manufacturing

Create a single part by combining two separate or more during molding but complimentary thermoplastic materials

Embedding secondary parts into the plastic injection molding process, the most popular metal threaded inserts and bushing

Allow for coloring or transparency in the finished product, highly suitable for products performance, durability and high quality are a necessity.

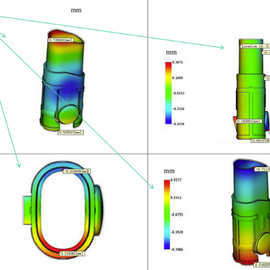

HundMold Quality Inspections

Quality is key when it comes to injection molding parts, so why not make sure you're getting the best product? With a variety of inspections processing assure that your parts will be up to all standards.

Plastic Injection Molding Finishes & Materials

From the smoothness of glossy plastics to the rugged durability of fiberglass, plastic injection molding is a versatile option for creating products with numerous finishes and materials.

- Plastic Injection Molding Finishes

- Injection Molding Materials

| Glossy | SPI-A1(Diamond #3 Polishing Grade-high polish) SPI-A2(Diamond #6 Polishing Grade-high polish) SPI-A3(Diamond #15 Polishing Grade-high polish) |

| Semi-Glossy | SPI-B1(Grit paper 600 -medium polish) SPI-B2(Grit paper 400 -medium polish) SPI-B3(Grit paper 320 – medium-low polish) |

| Matte | SPI-C1(Stone 600 -low polish) SPI-C2(Stone 400 -low polish) SPI-C3(Stone 320 -low polish) |

| Textured | MT (Moldtech) VDI (Verein Deutscher Ingenieure) YS (Yick Sang) |

| Material | Material Full Name | Common Properties | Common applications |

| ABS | Acrylonitrile Butadiene Styrene | Perfect for projects that demand strength, stiffness, and impact resistance. It can be painted, and glued and is easy to recycle | Enclosures, Automotive, Sports Equipment, Toys |

| PP | Polypropylene | The second most widely-produced plastic globally, tough, fatigue- and chemical-resistant, but vulnerable to UV radiation and flammable. | Kitchen Supplies, Food Packaging |

| PC/ABS | Polycarbonate-Acrylonitrile Butadiene Styrene | A blend of polycarbonate and ABS, good heat resistance and flexibility | Enclosures, large panels |

| PMMA | Polymethyl Methacrylate | Often used as an impact–resistant replacement for glass, UV and light resistant and will not fade, good impact resistant | Lenses, medical devices, screens, furniture, paint, beauty products |

| PA 6/6 | Polyamide 6/6, Nylon 6/6 | strength and rigidity | Automotive applications, gears, bushings |

| Glass Filled & PA 6/6 | durable and flexible | Bearings, washers, a lightweight substitute for metals where appropriate | |

| PS | Polystyrene | Often used to create single-use products, odorless and non-toxic | plastic cutlery, electronics, toys, and auto parts |

| ASA | Acrylonitrile Styrene Acrylate | As an ABS alternative with improved weather resistance | Enclosures, Automotive parts |

| HDPE | High-Density Polyethylene | Superior moisture resistance,good impact strength, and chemical resistance, not suitable for products that require Weather resistance that must withstand high temperature | Toys and computer components, Caps and enclosures |

| LDPE | Low-density Polyethylene | Flexible, light weight, good water and chemical resistant | Medical container, food packaging |

| POM | Polyoxymethylene | Good dimensional stability, low friction, and high rigidity | Bearings, fasteners, guns, knife handles, lock systems, automotive parts |

| LDPE | Low-Density Polyethylene | Soft, flexible, tough, and lightweight plastic with good corrosion resistance | Tubing, Containers |

| PEEK | Polyetheretherketone | High temperature, chemical, and radiation | Medical product |

| SAN | Styrene Acrylonitrile | Higher thermal and chemical resistance |

Packaging |

| PET | Polyethylene terephthalate | Most common material for plastic bottles of water and other drinks | Drink bottle |

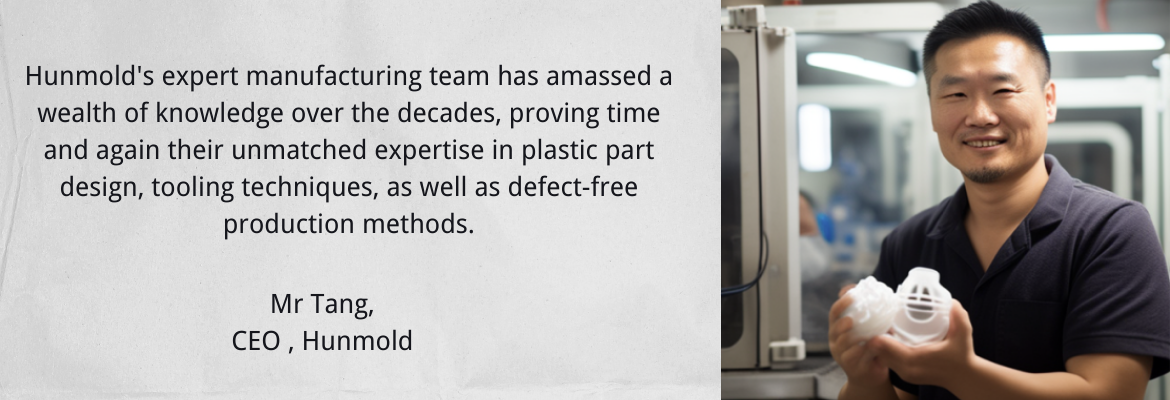

Why Choose HunMold

Hunmold's expert manufacturing team has amassed a wealth of knowledge over the decades, proving time and again their unmatched expertise in plastic part design, tooling techniques, as well as defect-free production methods.

Competitive Factory Direct Injection Molding Price

From 10 of parts to thousands, over ten thousand, our own production facility to lower production cost. No MOQ request.

Strictly Quality Control

Our injection molding experts with 10 + experience will build a comprehensive design for manufacturing review comes with prototyping, design validation, and production applications to avoid common mistakes, make smart decisions, and execute your next project with ease

One-Stop Services

We offer tool-making and molding services. Our complete package includes materials selection, prototyping, mold design, LOGO printing, related parts sourcing, packing material sourcing, assembly, packing as well as door-to-door shipment.

How To Work With Us

With our comprehensive one-stop service, you can be sure that your projects will be completed efficiently with superior results.

① Request Manufacturing

Send your inquiry With 3D CAD or sample photo or sketch

② Get a quote with free DFM

Offer design-for-manufacturability analysis and prepare your quote within 24 hours

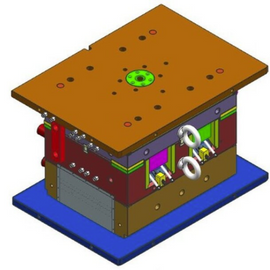

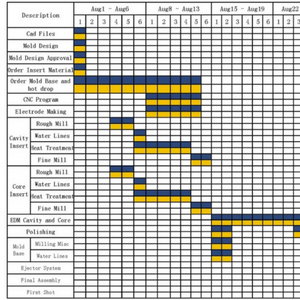

③ Tool Manufacturing

After mold design approval, the tool manufacturing starting

④ Weekly Progress Update

Progress Update with Photos and Videos

⑤ Sample Report

QC team inspect the dimension and out-looking and give the samples report

⑥ Samples

Produce samples, QC control, and deliver the samples

⑦ Production Parts

Once samples are approved, the samples, production is started

⑧ Delivery

Your manufacturing parts are delivered to your Door

⑨ Reorder your parts

Easily reorder the manufacturing parts from your tooling

Design Tips

Crafting molded parts can be a tough but rewarding task and we're here to help you every step of the way! With our design tips, anyone can embark on their journey successfully; creating quality components quickly is just moments away.

Related Plastic Injection Molding Resources

Let’s Get Started

Get an injection molding design analysis and see what HunMold can do for you today.

Change Language

Change Language