Post Processing

Get ready to elevate the appearance and performance of your injection-molded plastic parts with Hunmold’s Post-Processing, Finishing Options. From adding functionality to creating a uniform look, we offer a variety of secondary operations for you to choose from to customize your product. With decades of combined experience in injection molding, our experts can guide you through the entire process – from design, to molding, to finishing. Plus, we offer secondary processes like printing, painting, welding, uv curing, hot stamping, laser engraving, electroplating, assembly, and packaging to create the ultimate finished product.

Silk screen printing is the go-to method for printing on flat and flexible plastic surfaces. This highly specialized process involves using a fine mesh screen covered by a stencil of the desired pattern. Multiple screens and stencils are used for complex images or multiple colors. The ink is squeezed through the mesh and onto the substrate surface where it’s not blocked by the stencil. With careful coordination, you can produce intricate, multi-colored prints, text, and patterns on any hard, flat surface. Silk screen printing is low-cost, versatile, and ideal for a wide range of applications.

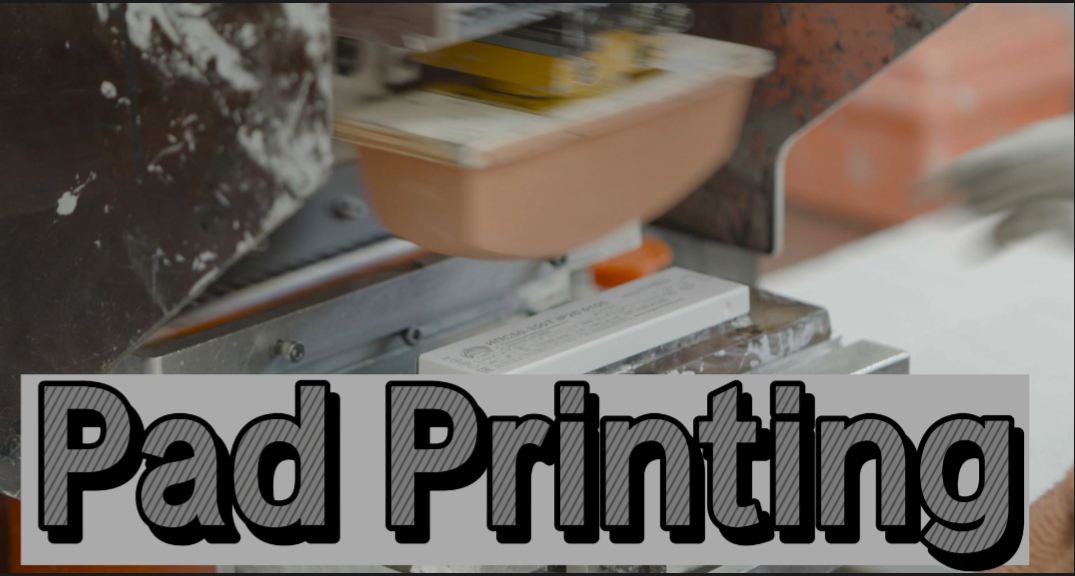

Pad printing is a process for placing colored graphics on parts, involving applying indelible ink-based, 2D design to a 3D surface. It can be done for branding, labeling, or part number identification.

Spray painting is the processing requires a spray gun or aerosol can apply a fresh coat of paint to a plastic surface. Just prepare your surface by cleaning it meticulously, roughing it up with sanding, and then spraying the paint evenly in thin layers for an immaculate finish.

Spray painting is the processing requires a spray gun or aerosol can apply a fresh coat of paint to a plastic surface. Just prepare your surface by cleaning it meticulously, roughing it up with sanding, and then spraying the paint evenly in thin layers for an immaculate finish.

Powder Coating is getting durable, dazzling finishes on plastics parts, with this post-process, a fine acrylic powder is electrostatically applied onto the part’s surface and heated with UV lamps for a tough and reliable adhesion. No more chipping or flaking like those typically caused by paint!

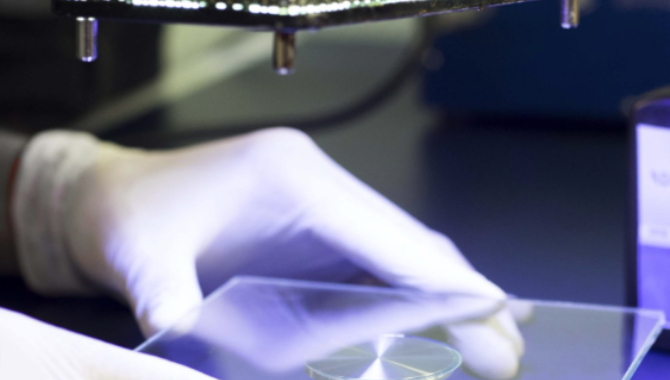

UV Curing process uses high-intensity ultraviolet light to dry and cure coatings and adhesives with impressive speed. Perfect for coating, printing, embellishment, and assembly of various products and materials. Unlike traditional methods, UV curing uses polymerization instead of evaporation – which means no more waiting around for your project to dry!

Hot stamping (also known as foil stamping) is a printing technique that uses colored films rather than traditional inks. The outcome is high-quality graphics that are either raised or depressed on the paper surface, creating eye-catching visuals. This unique method works by transferring a printed image to the printing surface using heat and pressure. Elevate your printing game with hot stamping and make your designs a standout success.

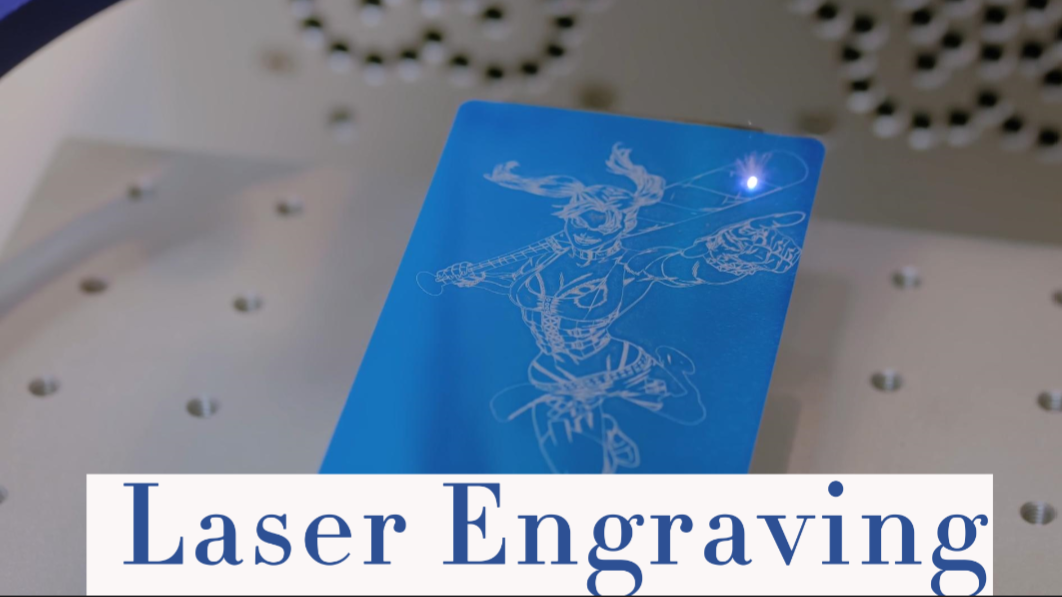

Laser engraving uses high-powered lasers to vaporize specific areas on any material, creating permanent markings with unbeatable contrast. Perfect for barcodes, serial numbers, logos, and more, laser engraving is a reliable and highly-effective way to enhance product traceability, identification, and decoration. Embrace the power of laser technology and take your product marking to the next level!

Ultrasonic Welding process utilizes high-frequency mechanical sound waves to generate molecular heat between thermoplastic materials. This process causes the plastic to seamlessly melt together, creating a solid molecular bond between parts that is unmatched in strength and precision.

Electroplating is a process that deposits a sleek metal layer, boosting appearance, resilience, and conductivity. Ideal for automotive, electronics, and consumer goods, electroplating is the answer to durable and impressive plastic parts.

Assemble your parts hassle-free in Hundmold. Just give us the materials and we’ll take care of everything else. Your parts will arrive fully and efficiently assembled, ready for use.

We offer packaging options such as clamshell/blister packs, boxes, and insert header cards, to ensure your product is prepped and ready for sale or shipment upon delivery. With us, you can trust that your packaging needs are in good hands.

Pad printing is a versatile solution for adding your brand or other information to your injection molded parts. With its ability to adapt to irregular shapes and surfaces, and produce detailed images with precision, its advantages include:

– Clear and uniform printing on challenging or complicated substrate materials.

– Perfect for transferring finely detailed images, including instructional graphics and text.

– Cost-effective for high-volume parts with repeatable and precise results.

– Great for limited color needs, accommodating up to four colors.

– Quality printing with detailed results, even in small areas.

Get the results you need for your branding with the advantages of pad printing.

Pad printing is a highly adaptable printing process that finds its applications in various industries. Its real-life use cases include but are not limited to, medical devices, caps and closures, decorative designs/graphics, automotive parts, TV and computer monitors, identification labels, and serial numbers.

Amorphous polymers like ABS, Acrylic, Polycarbonate, and PVC are your best bets! They’re perfect for this process due to their lack of crystalline structure. If you’re set on using semi-crystalline materials like Polyethylene, Polypropylene, Polyester, or Nylon, just know that they might require a bit more effort to weld.

1. Ensure uniform contact area

To optimize energy transmission in the joint area, the parts being joined should be in intimate contact around the entire joint on one plane. This will enable the horn to make direct contact over the joint area and focus the transmission of mechanical energy to this point.

2. Start with a small initial contact area

To minimize the energy and time needed to melt the mating parts, the initial contact area between the parts should be small. This is achieved through the use of an energy director – a triangular-shaped protrusion around the entire joint. This also minimizes scuffing and flash generated, making the entire welding process much smoother.

3. Effective alignment methods

For a precise joint that is repeatable, it is important to provide a means of alignment between the parts. Features such as pins and sockets, steps, or tongues and grooves should be used for alignment, rather than relying solely on the vibrating horn and fixture, which can result in marking.

Ultrasonic welding for plastic is rapid and efficient. You can insert and remove a part from the welding machine within a matter of seconds, saving you valuable time and reducing costs on power and fuel. Unlike other welding methods, ultrasonic welding requires lower temperatures, yet delivers a strong and lasting bond for your plastics. With adhesives, you may need additional time for curing, but ultrasonic welding is fast and produces instant results. Choose ultrasonic welding for a cost-effective, time-efficient, and superior quality plastic manufacturing process.

Change Language

Change Language