Our CNC Processes

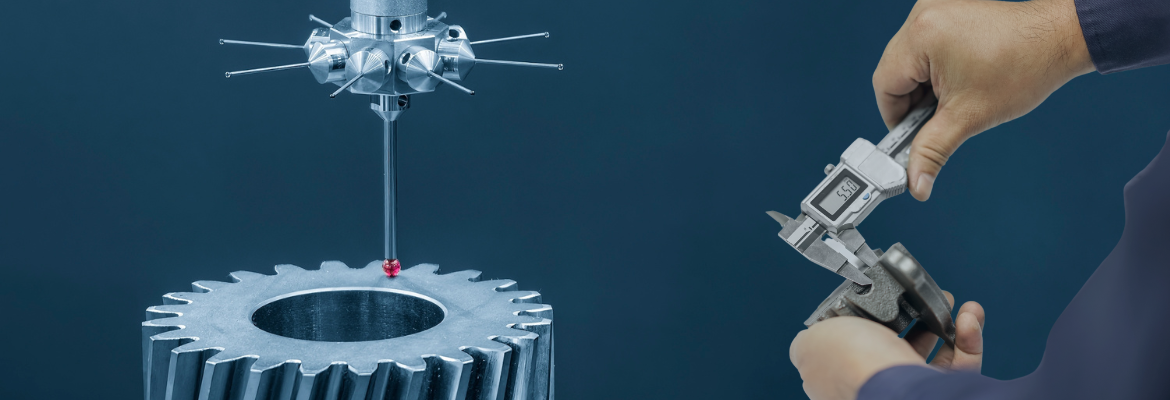

Get precision and speed with CNC machining. This versatile manufacturing process, which stands for computer numerical control, uses automated cutting tools to shape metal or plastic stock according to your design specs. Choose from standard 3-axis, 4-axis, and 5-axis milling machines, lathes, and routers to cut a variety of metal alloys and rigid plastics with amazing accuracy and consistency. With custom-machined parts for just about any industry, CNC is your go-to solution for quality and reliability.

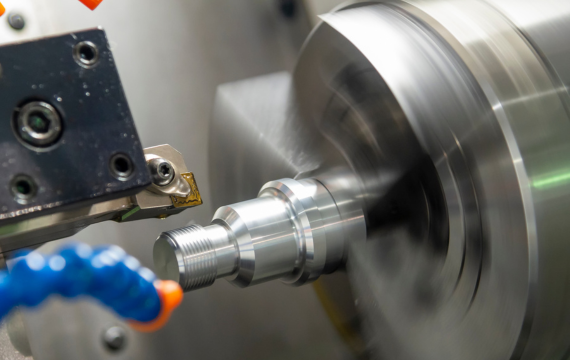

Experience the pinnacle of precision manufacturing with CNC turning. Craft deep holes, flawless machined threads, and impeccable cylindrical shapes boasting superior surface finishes. At Hunmold, we deliver precisely manufactured parts with lightning-fast turnaround and no volume limitations. Discover how we can support your manufacturing needs today.

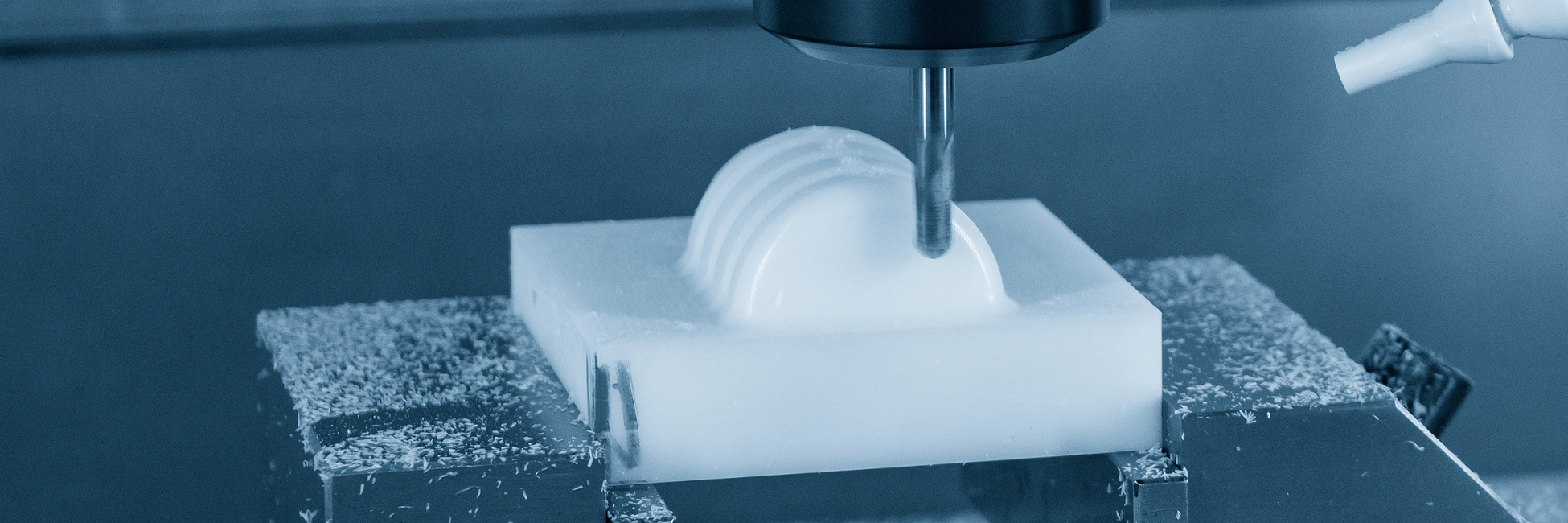

Witness the marvels of CNC milling as raw materials are meticulously sculpted. From a solid block, the CNC mill breathes life into desired parts, guided by the magic of G-code. Experience the precision of a three-axis system, crafting plastic or metal components with unrivaled accuracy.

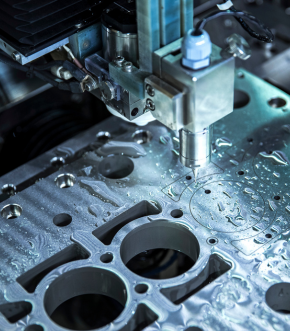

Electrical discharge machining (EDM) with extraordinary precision-controlled electrical pulses expertly erode the toughest metals. This specialized form of CNC machining is indispensable for working with hardened tool steels, delivering mirror-smooth surface finishes that eliminate the need for additional polishing

Achieve unparalleled surface flatness with precision surface grinding. Our state-of-the-art CNC machining service utilizes specialized abrasive wheels, guided by digital motors, to ensure flawlessly flat parts. Reach out to us today and discover how this technique can elevate your manufacturing needs.

CNC Materials

HunMold has multitude of material options to meet your CNC machining needs! From rapid prototyping to production runs of custom complex parts, we've got you covered. Get an inquiry to know our a range of metals and plastics, you can easily compare prices and choose the perfect machining material for your project. Transform your manufacturing process with our comprehensive selection of CNC machining materials.

- CNC Machining Plastic Materials

- CNC Machining Metals Materials

| CNC Machining Plastic Materials | ||

| Materials | Description | Price |

| ABS | Not only is it easily machinable, but it also maintains its shape for consistent production | $$ |

| HDPE | Durable and dependable, boasts impressive resistance to impact, tensile strength, and protection against chemicals and corrosion. | $ |

| LDPE | Easily machinable, good chemical and corrosion resistance. | $ |

| Nylon | Boasts exceptional bearing and wear capabilities, along with top-notch mechanical properties. | $$ |

| PP | With exceptional chemical resistance and excellent flexible | $ |

| PC | Clarity and durability with our high-impact, naturally transparent product. | $$$ |

| PMMA / Acrylic | Durable and transparent thermoplastic with unbeatable resistance to UV radiation | $$ |

| POM (Delrin) | Superior efficiency with low friction and high stiffness | $$ |

| CNC Machining Metal Materials | ||

| Materials | Description | Price |

| Aluminum | Easily to machine. With excellent machinability, strength, and electrical conductivity | $$ |

| Brass | It is unaffected by extreme weather and corrosion. With comparable tensile strength to mild steel, it’s the ultimate in durability. | $$$ |

| Copper | Pure Excellence with superior electrical conductivity | $$$ |

| Stainless steel | Superb machinability and remarkable uniformity, paired with excellent workability and weldability. | $$ |

| Steel | Superb machinability and unmatched electrical conductivity | $$ |

Why Choose HunMold For CNC Machining Services

Discover Hunmold's unparalleled CNC machining services, where speed, flexibility, and uncompromising quality converge. Experience the difference that sets us apart from the competition. Delve into our precision manufacturing and unlock a new level of excellence

24/7 Manufacturing Analysis

When submitting your 3D CAD file for a quote triggers our detailed geometric analysis, we meticulously examine your design to identify potential machining challenges, such as excessively tall, thin walls, or unthreadable holes, our experienced engineers are available 24/7, year-round, to guide you on design optimization, material selection, finish options, and lead tim.

Fast and Reliably Delivery

Speed up product development with rapid part design iteration and quick-turn parts. Our automated analysis identifies machining challenges early, preventing costly reworks and enhancing efficiency in the manufacturing process.

Reliable High Quality with Good Price

Capitalizing on our CNC machining processes and advanced technology, we promise price points that stand toe-to-toe with market offers. In our unwavering commitment to excellence, we rigorously enforce IS9001 system standard, coupled with comprehensive inspections, to guarantee you receive precision machined parts, consistently maintaining expected standards and free from undesirable defects

How To Work With Us

With our comprehensive one-stop service, you can be sure that your projects will be completed efficiently with superior results.

① Request Manufacturing

Send your inquiry With 3D CAD or sample photo or sketch

② Get a quote with free DFM

Offer design-for-manufacturability analysis and prepare your quote within 24 hours

③ CNC Machining Manufacturing

After order detail approval, the manufacturing starting

④ Progress Update

Progress Update with Photos and Videos

⑤ CNC Machining Products Report

QC team inspect the dimension and out-looking and give the samples report

⑥ Delivery

Your 3D Printing Products are delivered to your Door

Design Tips To Reduce CNC Machining Costs

Hunmold, by executing thoughtful alterations to part design or material choices, can effectively decrease the cost of machined components while enhancing functionality. Optimizing features like corner pockets, engraved text, thin walls, deep pockets, holes, and intricate geometries can significantly boost the design's machinability.

Related CNC Machining Resources

Let’s Get Started

Get an injection molding design analysis and see what HunMold can do for you today.

Change Language

Change Language