Injection Mold Processes

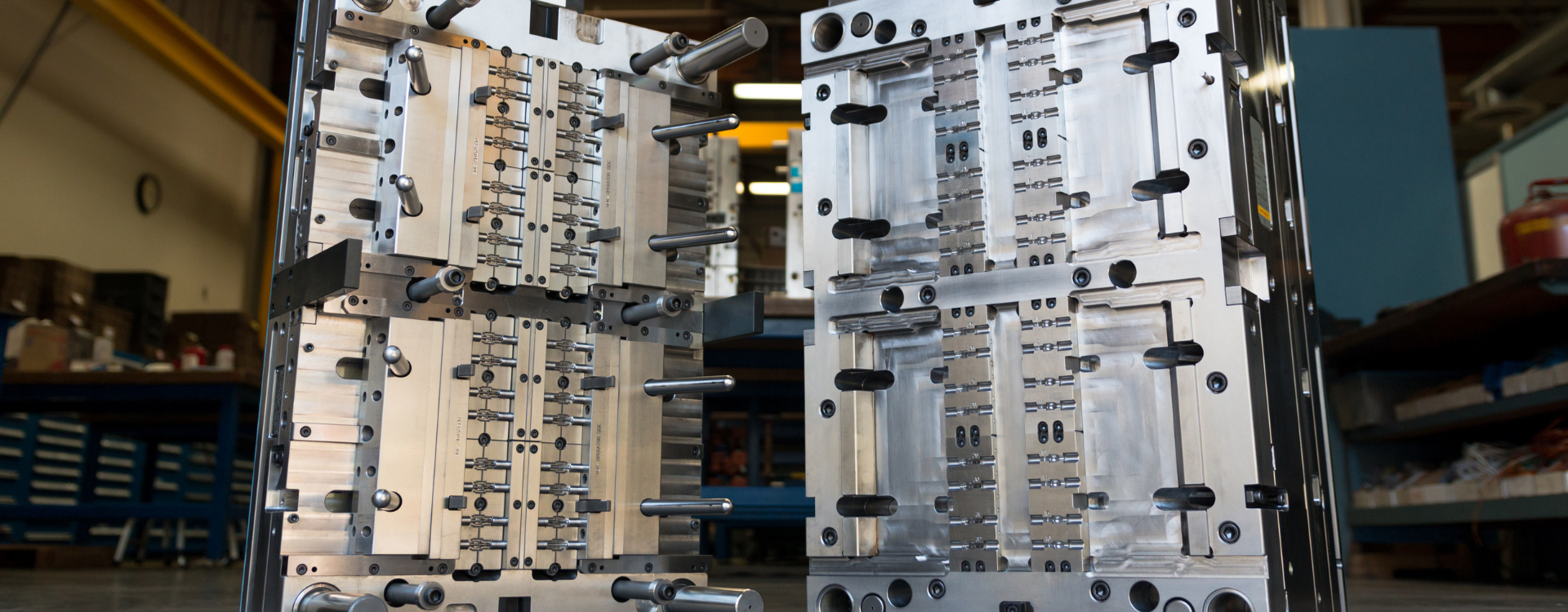

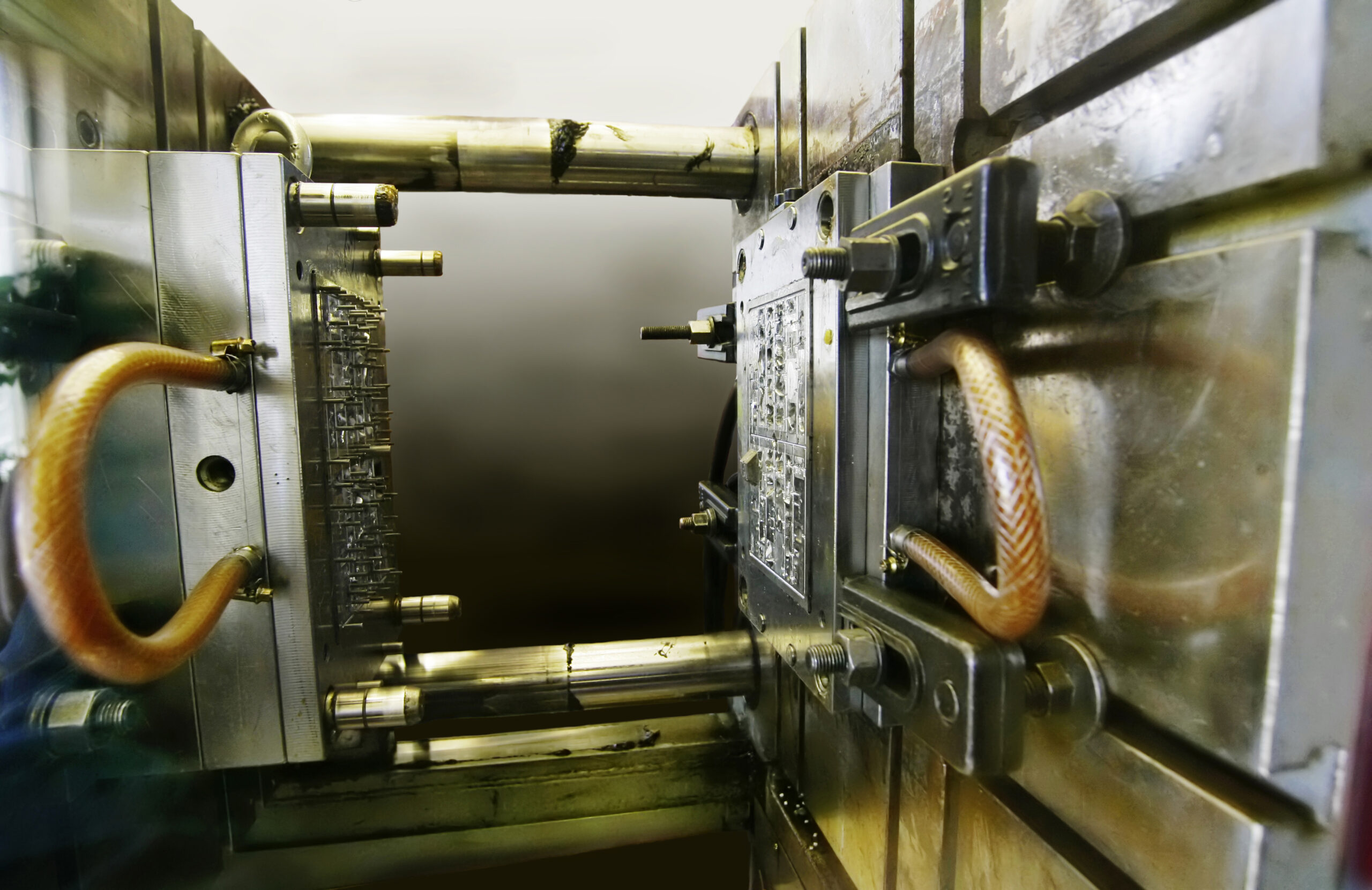

Injection mold, also known as mold tooling, is composed of two formed halves of a metal mold that unite within an injection-molding machine. Once molten plastic fills the mold cavity, it will have two sides- the cavity and core sides (or Side A and Side B). Usually, Side A provides the most appealing surface of the item, whereas Side B may contain visual imperfections caused by ejector pins. These pins help knock out the previous part so that another one can be molded.

Types of Plastic Injection Molds

Steel Mold Materials Choose

The construction of plastic injection molds is a balancing act between the budget and the necessary end product. To ensure quality, most molds are produced from steel and aluminum. Hunmold combines cutting-edge CNC machining and EDM equipment, a range of steel materials for you to choose to create best-in-class results that satisfy our customer’s exact requirements

- Steel Mold Materials Choose

| Mold Materials Choose | |||||

| P20 steel | 718 steel | NAK80 | H13 | S136 | |

| Description | reliable, semi-hardened tool steel | commonly used in xx by special production process have 41 ~ 47HRC pre-hardened ex-factory, with cost-effective | semi-hardened tool steel, a common use for highly polished clear or glossy plastic parts. | needing larger volume production orders mold steel with good resist wear | a grade of high-purity stainless steel with larger volume production demand |

| Pros | Faster machining P20 steel is harder than 45 steel Easily welded |

Good polishing, Good wear resistance high tensile strength |

Good Polishing Larger Mold Life |

Tight tolerance Good resistance the corrosive chemicals |

Perfect Polishing Good resistance the corrosive chemicals, like PVC and POM |

| Cons | Not resistant- P20 steel is not very resistant to chemically corrosive material, like PVC | Price higher than P20 steel | Price is higher Longer Delivery Time |

Price is higher Longer Delivery Time – It needs to heat treated after |

Longest delivery time High tooling cost |

| Mold life | 5,000-100,000 shots (depending on the plastic material and part design) | 200,000-300,000 shots | 300,000-400,000 shots | 500,000 -800,0000 shots | 800,000-1000,0000shots |

| Application | resins, abrasive resins with glass fibers Items, with limited budget and volumes | High-volume production &Good Polish Plastic Parts |

High-volume production Perfect Polish Plastic Parts |

High-volume production | PVC and POM High-volume production orders |

| Price | $ | $$ | $$$$ | $$$$ | $$$$$ |

Why Choose HunMold for Injection Mold Making Services

Hunmold has been producing plastic injection molds and plastic parts for various industries including medical, automotive, sports, hunting/camping, electronics, food/beverage, containers, packaging, and more, and has been delivered to numerous companies worldwide.

Inexpensive Injection mold

We manufacture tooling and mold adjustment in-house, saving 20% additional charge, unlike other injection molders that send molds out to machining.

Quality Guarented

We have 20 sets of high-precision mold-making equipment to ensure the quality of processing, and our staff of custom mold technicians to make smart decisions and execute projects. And we will store and maintain that mold indefinitely when customers continue to reorder parts at least once per year.

Instant Quote With FREE DFM

The Design for Manufacturing analysis will provide with price in 24 hours.

How To Work With Us

With our comprehensive one-stop service, you can be sure that your projects will be completed efficiently with superior results.

① DFM

Improve the performance and cost-effectiveness of your injection molded parts with design-for-manufacture optimization services。

② Mold Flow Analysis & Mold design

We simulate, optimize, and predict the performance of your molds early in the drawing process to create efficient and cost-effective molds for all your needs.

③ Material Procurement And Inspection

Purchasing mold base inserts and EDM electrodes in high-quality raw materials.

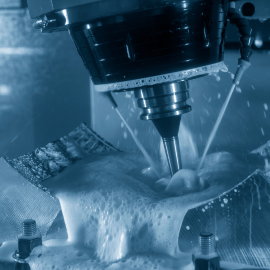

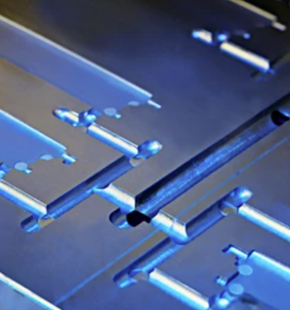

④ CNC machining & EDM& Grinding

Our mold CNC & EDM& Grinding machining gives you reliable high-quality molds made with steel, aluminum, and more.

⑤ Mold Assembly& Mold Polishing

Assemble the two halves of the mold to ensure line up perfectly, and polish molds to remove machining marks.

⑥ Mold Trial

Create samples from your latest molds, so you can visualize how your final customized molded parts will look like.

⑦ Improvement if needs

Our team conducts a thorough analysis of each sample, carefully reviewing molds by CMM machines and discussing with you the mold design, and making necessary adjustments for optimal results.

⑧ Delivery

Get molds or parts delivered right to your doorstep! We custom-manufacture each mold to meet your exact specifications before shipping it off to you.

⑨ Storage and regular mantenance tools

Provide keeping store your molds to ensure they stay in prime condition if you want us to keep them here.

Mold Design Tips

To ensure quality parts, the mold must be built correctly. Avoid cost-cutting when shopping for injection mold, as defects are likely to arise down the road. Working closely with the toolmaker is essential to developing a mold that can meet your specific needs and prevent defects. Some tips for injection mold designing include understanding the needs of the end user, optimizing the gate size and location for efficient fill.

Related Plastic Injection Mold Resources

Let’s Get Started

Get an injection molding design analysis and see what HunMold can do for you today.

Change Language

Change Language