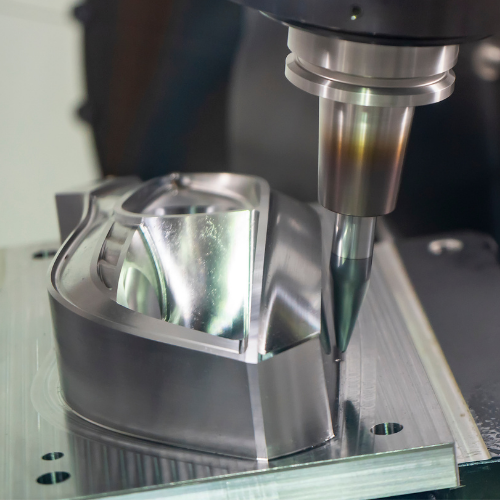

Tooling making and injection molding production are in house, save 25% additional cost

Strictly followed ISO 9001:2015 certified, dedicated to making high quality parts, you and your customers will love.

We have advanced technical equipment and technical team, according to the different needs of customers to provide specialized solutions

Provide design, prototyping, build injection molds, run production, LOGO printing, related parts sourcing, assembly,packing and door- to -door delivery.

How To

Work With Us

- Send Your Drawing

- Design Feedback Report

- Manufacturing Staring

- Quality Control

- Parts Are Shipped

Waiting a few days or weeks to get your quotes back with ?

HunMold give your quote instantly or within hours. We accept below type drawing

- IGES (.igs)

- STEP (.stp)

- Parasolid (.x_t)

- ProE (.prt)

- .stl files

- PDF Drawing

- Draft Drawing

- Your Idea

Design Feedback Report

Free analyze your parts , to help identify any features that maybe challenges during the molding process . Design Feedback analyze contain :

- Sink Mark

- Undercut

- Draft Angle

- Deformation

- Short Shot

- Weld Line

- Assemble Structure

Manufacturing Starting

Manufacturing Starting

When you place ttheorder, we’ll provide the DFM Reports (about parting line, location of injection gate etc) Mold Flow Analysis , Mold Design. Once we confirm all the details, manufacturing process will be started. Your project schedule updated weekly with photos.

- DFM Report

- Mold Flow

- Mold CAD drawing

- Manufacturing Weekly Update With Photos

Quality Control

Sample & Production Pieces Quality Control Report For Dimension and Appearance will be sent to you. Sample Report will be provided that include :

- Part Appearance Checking

- Dimension checking

- Full inspection

- Assmeble Testing

Parts Are Shipped

Getting Your Approval to ship parts, One- Stop Services from our factory to your place will be arranged.

- Parts Packed

- Door- Door Shipment Support

- After Services

We‘re Your Manufacturing Partner

- Five Engineers

- 50 matured mold making & production workers

- Strictly followed ISO9001 -2016 certification

- One-Stop services From Prototype to Production, Assemble, and Door To Door Shipment

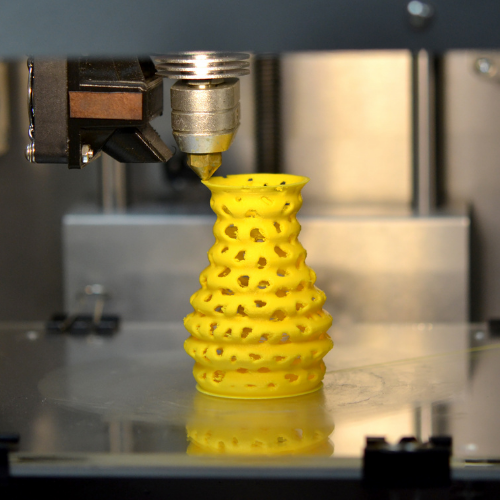

HunMold's Injection Molding Services

Hunmold’s goal is to help you manufacture plastic parts faster, easier and efficiently, to be your best assistant.

Quality You Can See From Beginning To End

- Weekly Progress Updates With Photos& Videos &Docs

- Parts Quality Inspection Report

- Issue Resolution Support

- The corresponding overseas sales and professional 5 engineers are responsible for your projects from start to finish

Comprehensive Capabilities

From Prototype to Production One-Stop Services

Numbers We are Proud of

Let the customer satisfied with our tooling , parts and service is our company’s philosophy of doing things

HunMold shipped over 100,000 parts with guaranteed quality to our worldwide customers.

Dedicating in plastic industry for 10+ year follow ISO9001 standard, HunMold provide problem solving.

What Our Customers Say

-

Chris BayonFrom Pirani L

Chris BayonFrom Pirani L -

Chris Macierfrom Helmet G

Chris Macierfrom Helmet G -

Terry Gilsenan, Mechanical Engineerfrom Sweet B

Terry Gilsenan, Mechanical Engineerfrom Sweet B -

Nieves Dorefrom Lockhart P

Nieves Dorefrom Lockhart P

Amazing, really luck to meet HunMold. Supply me good quality product, everything is nice.We have done many testing, our customers are satisfied with it. Really thanks, hope we will have a long cooperation.

HunMold is incredible to work with, perfect attention and quality of work , also to the attention at all times of Peni. I fully trust them.

The products received were even better than I hoped them to be, it was hard to tell the product quality from the photos. Thank you Hunmold.

The best part of working with HunMold is their sales Kai. He gave me excellent suggestions for improvement in both quality and cost savings. As an engineer I appreciate someone who can take our design and work with the production team to create a final product we can all be proud of. Thank you again Kai.

Change Language

Change Language