Our 3D Printing Processes

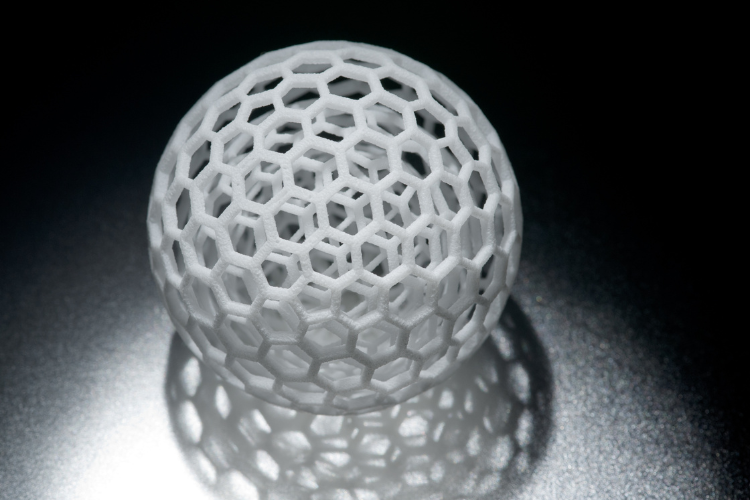

This technology is revolutionizing the industrial world, opening up endless possibilities for production. With 3D printing, you can speedily and effectively create intricate parts, using top-grade resins and plastics. Plus, the sky's the limit when it comes to customization. Not to mention, the finishing and post-processing options are practically endless.

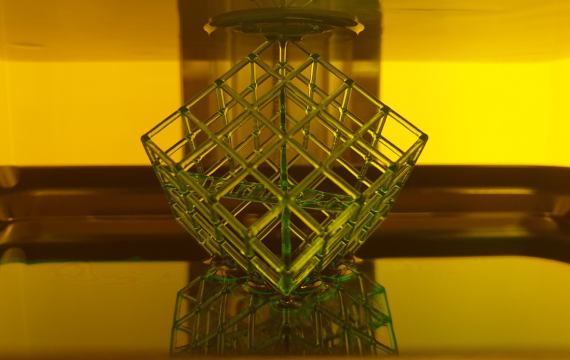

Stereolithography (SLA) for producing parts with stunning surface finish and exceptional feature resolution. Although not ideal for high-performance applications, it is an excellent choice for making detailed and precise prototypes.

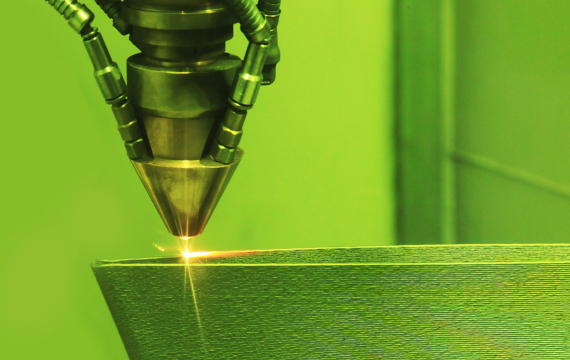

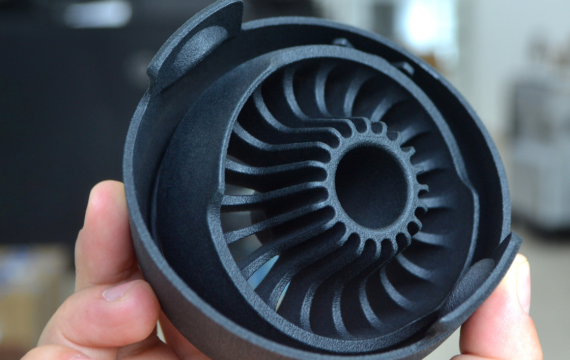

Selective laser sintering (SLS) is a cutting-edge technology that utilizes lasers to fuse powder materials layer by layer, resulting in highly durable and reliable parts and components. This process is perfect for functional, high-stress applications.

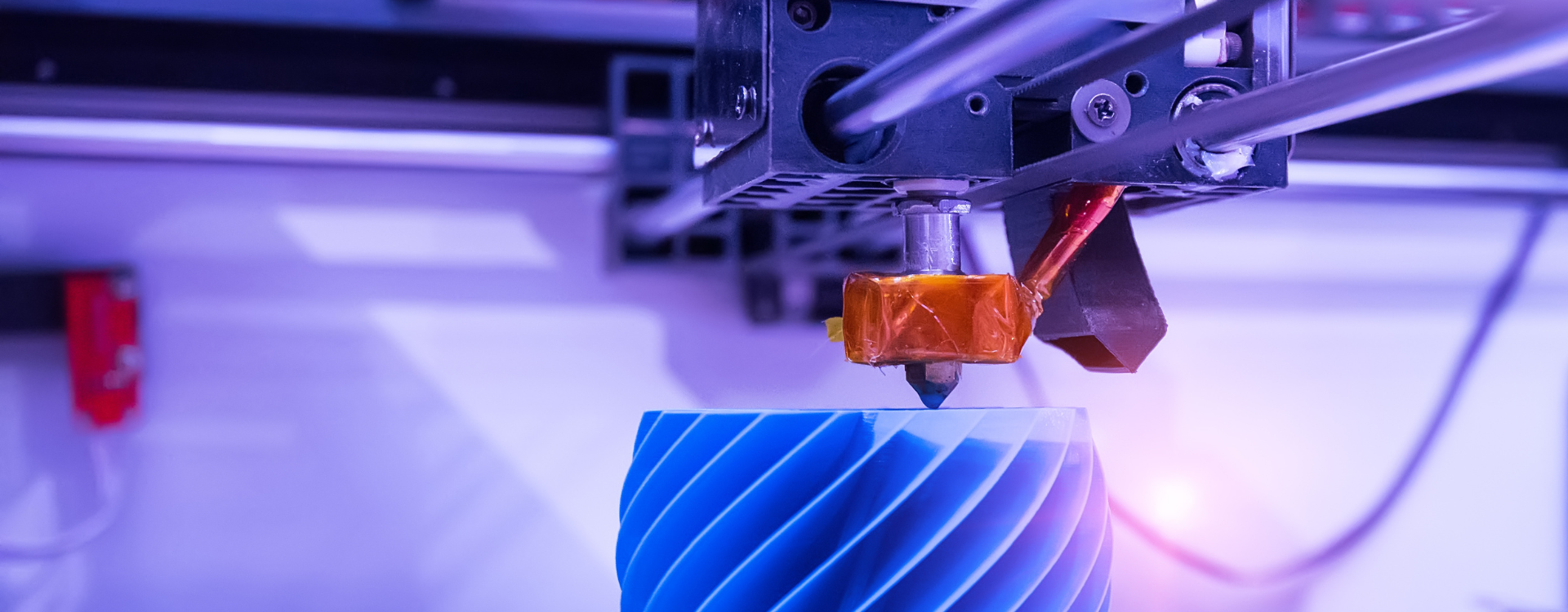

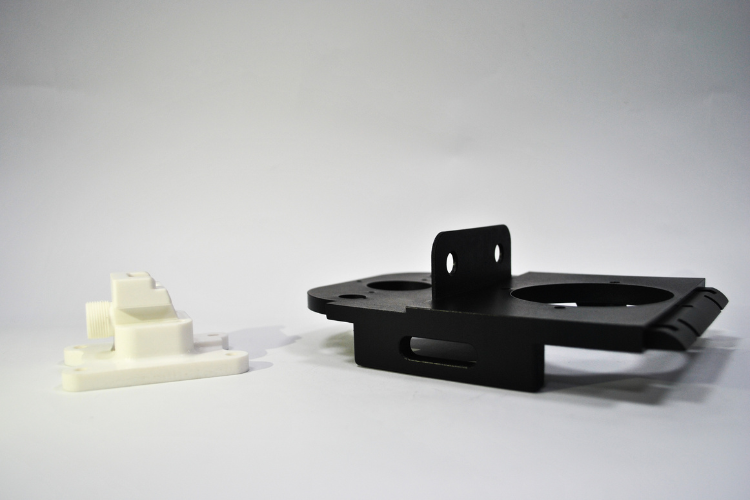

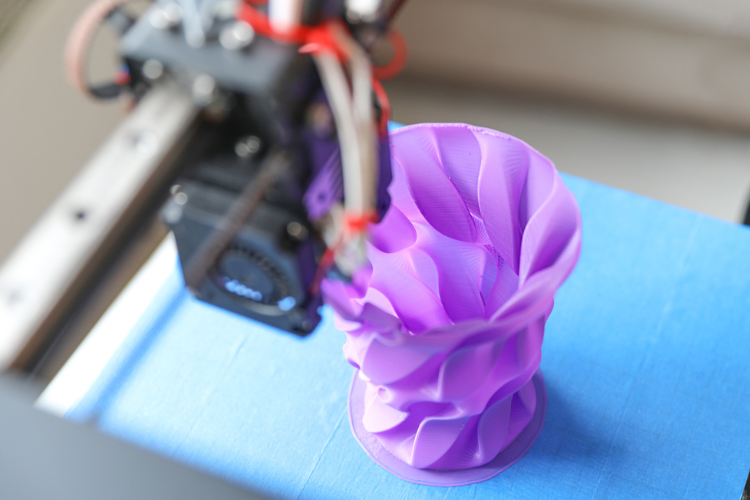

FDM is a cost-effective 3D printing method that melts thermoplastic filament material and accurately constructs complex 3D models by extruding it onto a platform

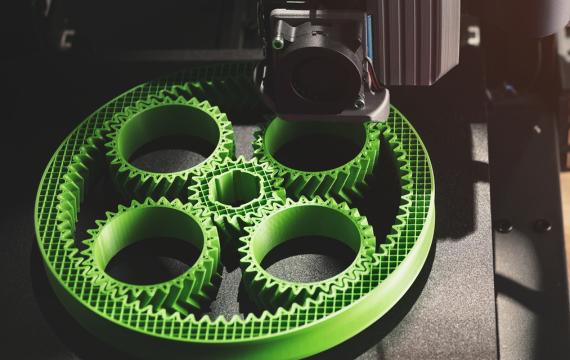

Multi Jet Fusion (MJF) is a cutting-edge 3D printing process that uses powdered thermoplastics to quickly produce intricate and precise parts. Not only do MJF parts have high tensile strength, but they also boast fine feature resolution, making them ideal for complex industrial parts.

Advantages of 3D Printing

Create one-of-a-kind parts or small batches with ease, this process can bring even the most complex geometries to life,

3D Printing Materials

HunMold has a wide range of materials for 3D printing and can select or recommend the right material for your product depending on its function.

- 3D Printing Materials

| Processing | Material |

| SLA | Resin 8228: ABS-Like Material. |

| Resin 8119: A popular SLA material that can withstand temperatures of up to 65°C. | |

| Resin 8338: The ultimate temperature-resistant solution that can endure scorching temperatures up to 120°C. | |

| Resin 8118H: Nylon-like material. | |

| PP-like: With tensile and flexural strength, along with high impact resistance. | |

| PC- Like: With high-temperature resistance and attain functional transparency through secondary processing. | |

| FDM | Nylon: It is a strong and flexible material that is resistant to wear and chemicals, making it a good choice for tough situations. Be aware, though, that humidity can impact its performance. |

| ABS: This material is the cost-effective solution for creating robust initial designs. Its strength is unmatched in the early stages of prototyping, providing you with reliable and functional prototypes. Plus, with post-processing options, ABS can offer an even better surface finish than other materials. | |

| PP: Polycarbonate (PC) filaments create mighty parts that defy both high temperatures and hard impacts. | |

| PLA: The go-to material for FDM enthusiasts. It’s cheap, rigid, durable, and offers an array of exciting colors. | |

| SLS | Nylon: Nylon 11 and 12 are the SLS materials with unbeatable mechanical strength, thermal and chemical resistance, and remarkable long-term stability. |

| MJF | Nylon: This sturdy material is perfect for designs featuring living hinges. |

Our Quality Promise

At Hunmold, you can breathe easy knowing that every part is manufactured with guaranteed quality and consistency. We meticulously inspect every order for precise dimensions and visual perfection, ensuring it meets our high standards. Trust Hunmold to take the stress out of manufacturing.

Inspection reports

We offer comprehensive visual and dimensional assessments report that include vivid images and a clear characterization of defects. Such as, surface finishes, tolerances and dimensions, threads, materials, parts finishing and cleaning, and packaging for your convenience. For every defect, we name the issue and assign a criticality level. To drive our point home, we provide actual examples of the defect in question (bad photo) and also show an acceptable part (good photo). We go above and beyond to deliver top-notch quality in our services and reports

Cosmetic Services

We offer top-notch post-processing solutions for your manufacturing needs.

MJF and SLS : guarantee powder removal.

FDM: We ensure that all surfaces have a uniform appearance, are free from excess support/build material and support structures (if applicable) are removed. To maintain consistency across large quantities, we print all parts on the same machine, avoiding any awkward mismatches.

SLA: All support materials are removed, support nibs are sanded smooth using both coarse and fine sandpapers (ranging from 80 to 220 grit) to achieve a fine, continuous surface. You can trust us to deliver outstanding quality every time!

Quality guaranteed

We prioritize delivering high-quality parts that meet your specifications. If they don't, rest assured that we'll make it right. Our commitment to excellence ensures that you receive top-notch products every time.

How To Work With Us

With our comprehensive one-stop service, you can be sure that your projects will be completed efficiently with superior results.

① Request Manufacturing

Send your inquiry With 3D CAD or sample photo or sketch

② Get a quote with free DFM

Offer design-for-manufacturability analysis and prepare your quote within 24 hours

③ 3D Printing Manufacturing

After order detail approval, the manufacturing starting

④ Progress Update

Progress Update with Photos and Videos

⑤ 3D Printing Products Report

QC team inspect the dimension and out-looking and give the samples report

⑥ Delivery

Your 3D Printing Products are delivered to your Door

3D Printing Design Tips

Discover the Top Design Tips for 3D Printing Prototypes! Elevate the quality of your printed parts by following these simple guidelines. Don't wait, reach out to us now to get access to expert advice on optimizing your 3D printing designs.

Related Plastic Injection Molding Resources

Let’s Get Started

Get an injection molding design analysis and see what HunMold can do for you today.

Change Language

Change Language